Sheet Metal Manufacturers who partner with Tesla Mechanical Designs see drafting expenses decrease by over 60%, enabling a game-changing business in Canada.

At Tesla Mechanical Designs, we harness innovation to drive cost savings and empower manufacturers to reach new heights of efficiency and success.”

— Divya Dave, Assistant Director at Tesla Mechanical Designs

ONTARIO, CANADA, January 30, 2025 /EINPresswire.com/ -- Tesla Mechanical Designs, a leading CAD Design company, unveils its pioneering outsourcing model that aims to help Canadian Sheet Metal Manufacturers cut their drafting costs by more than 60%. The company’s philosophy combines advanced CAD solutions with flexible drafting services, providing an

economical alternative for manufacturers looking to avoid the expense of full-time in-house teams. Manufacturers who partner with Tesla Mechanical Designs see drafting expenses 𝗱𝗲𝗰𝗿𝗲𝗮𝘀𝗲 𝗯𝘆 𝗼𝘃𝗲𝗿 𝟲𝟬%, providing a game-changing business throughout Canada.𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬 𝐈𝐧𝐭𝐫𝐨𝐝𝐮𝐜𝐞𝐬 𝐒𝐜𝐚𝐥𝐚𝐛𝐥𝐞 𝐃𝐫𝐚𝐟𝐭𝐢𝐧𝐠 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 𝐟𝐨𝐫 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐞𝐫𝐬

Canadian sheet metal manufacturers face growing difficulties in managing drafting and design expenses, which add to production challenges. Manufacturers must decide between keeping an in-house drafting department that is costly and lacks adaptability. The team might only be necessary during specific periods, but businesses must pay salaries and benefits throughout the entire year, even when there isn’t adequate work to warrant these expenses. The inefficiency in resource utilization drives up operational costs and diminishes company profit margins.

Tesla Mechanical Designs offers an alternative approach to 𝐢𝐧-𝐡𝐨𝐮𝐬𝐞 𝐝𝐫𝐚𝐟𝐭𝐢𝐧𝐠 𝐦𝐨𝐝𝐞𝐥𝐬.

Tesla Mechanical Designs has identified these financial obstacles and adopted a revolutionary method for manufacturing companies. Tesla Mechanical Designs provides outsourcing solutions which enable companies to obtain expert drafting services without incurring typical in-house team expenses. Manufacturers can save more than 60% on drafting expenditures through this model, allowing them to reallocate funds toward expansion and product innovation. Manufacturers can adjust their drafting resources to match specific project requirements, leading to improved workflow efficiency and reduced expenses.

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐅𝐚𝐜𝐢𝐧𝐠 𝐒𝐡𝐞𝐞𝐭 𝐌𝐞𝐭𝐚𝐥 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐞𝐫𝐬 𝐢𝐧 𝐂𝐚𝐧𝐚𝐝𝐚

Modern sheet metal manufacturers encounter increasing financial and operational difficulties when managing their drafting and design operations. Technology has advanced, but resource utilization inefficiencies and adaptability gaps continue, increasing production costs and delaying project timelines. The primary challenges manufacturers face include, but are not limited to:

✔ High Labour Costs: Maintaining dedicated in-house teams proves costly for businesses because they face challenges with varying project demands and inconsistent workloads.

✔ Inefficient Processes: The need for repeated drawings, manual calculations, and constant revisions leads to inefficient processes that prolong project timelines.

✔ Error and Rework: Mistakes made during manual drafting result in expensive rework, project delays, and wasted materials that ultimately drive up production costs.

✔ Limited Resource Optimization: Valuable resources often get tied up in drafting tasks, limiting investment in innovation and expansion.

Tesla Mechanical Designs developed its innovative strategy to address these challenges by integrating outsourcing capabilities with advanced design technology to reduce costs significantly.

𝗧𝗵𝗲 𝗧𝗿𝘂𝗲 𝗖𝗮𝗽𝗮𝗯𝗶𝗹𝗶𝘁𝘆 𝗼𝗳 𝗢𝘂𝘁𝘀𝗼𝘂𝗿𝗰𝗶𝗻𝗴 𝗮𝗻𝗱 𝗖𝗔𝗗 𝗧𝗲𝗰𝗵𝗻𝗼𝗹𝗼𝗴𝘆: 𝗧𝗲𝘀𝗹𝗮 𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝗰𝗮𝗹 𝗗𝗲𝘀𝗶𝗴𝗻𝘀

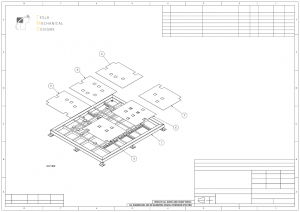

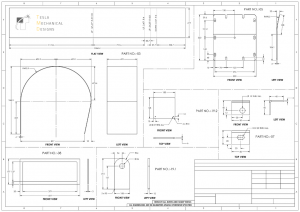

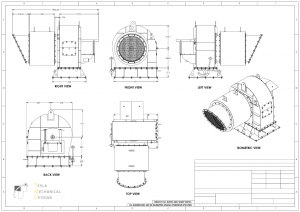

Tesla Mechanical Designs revolutionized the drafting process in sheet metal manufacturing by integrating modern design technology with outsourcing capabilities. Manufacturers leveraging fabrication drawing services gain substantial cost reductions while achieving quicker project completions and enhanced design accuracy. Here's how:

✔ Outsourcing for Flexibility and Scalability: Tesla Mechanical Designs enables manufacturers to avoid the high costs of internal teams by outsourcing their drafting and design tasks to a worldwide network of skilled professionals. Manufacturers can adjust their workforce size to meet project requirements with this method, which ensures they pay exclusively for necessary work.

✔ Technology-Driven Precision: Tesla Mechanical Designs employs cutting-edge CAD systems like SolidWorks and AutoCAD, enabling them to generate precise designs efficiently. This technology prevents errors while reducing revision time, producing superior final design quality.

✔ Streamlined Workflow: Through a combination of outsourcing and technology, Tesla Mechanical Designs’ team efficiently completes design iterations, allowing manufacturers to meet strict deadlines without compromising design precision.

✔ Reverse Engineering and Prototyping: Through reverse engineering, Tesla Mechanical Designs enables manufacturers to replicate current designs or create enhanced versions without starting from zero. Prototyping services would allow manufacturers to evaluate and perfect their designs before entering full-scale production, which helps avoid expensive errors.

Tesla Mechanical Designs provided manufacturers with a hybrid model that lowered their drafting costs by over 60% and allowed them to invest more in product quality improvement, production capacity expansion, and market reach enlargement.

𝗣𝗿𝗼𝘃𝗲𝗻 𝗥𝗲𝘀𝘂𝗹𝘁𝘀: 𝗢𝘃𝗲𝗿 𝟲𝟬% 𝗦𝗮𝘃𝗶𝗻𝗴𝘀 𝗶𝗻 𝗗𝗿𝗮𝗳𝘁𝗶𝗻𝗴 𝗖𝗼𝘀𝘁𝘀

The combination of Tesla Mechanical Design’s outsourced solutions and cutting-edge technology has generated outstanding outcomes for sheet metal manufacturers across Canada. Companies that partner with Tesla Mechanical Designs experience an average drafting cost decrease of more than 60%.

• Reduced Labour Expenses: Manufacturers reduce their in-house labour costs using skilled professionals who work at competitive rates without compromising quality.

• Improved Productivity: Advanced CAD software enables quicker iterations and revisions, boosting overall productivity and shortening project completion times.

• Precision and Accuracy: Tesla Mechanical Designs applies advanced CAD technology to achieve design precision, which leads to fewer mistakes and less expensive redesign efforts.

• Minimized Errors and Rework: Technology-driven precision in designs leads to fewer errors, reducing expensive rework while delivering superior quality at a reduced cost.

• Optimized Resource Allocation: Businesses redirect resources into product development, machinery upgrades, and marketing expansion because they save money on drafting costs.

• Reliability and Expertise: Tesla Mechanical Designs delivers exceptional reliability because their team brings vast industry experience to every project.

• Streamlined Communication: Tesla Mechanical Designs operates an outsourcing model that works perfectly with their project management systems to deliver real-time updates and consistent communication during the design process.

The financial 𝗯𝗲𝗻𝗲𝗳𝗶𝘁𝘀 𝗮𝗿𝗲 𝘀𝗶𝗴𝗻𝗶𝗳𝗶𝗰𝗮𝗻𝘁. Mid-sized manufacturers allocating $100,000 yearly for drafting services can 𝗮𝗰𝗵𝗶𝗲𝘃𝗲 𝘀𝗮𝘃𝗶𝗻𝗴𝘀 𝗲𝘅𝗰𝗲𝗲𝗱𝗶𝗻𝗴 $𝟲𝟬,𝟬𝟬𝟬 through their partnership with Tesla Mechanical Designs. The savings enable manufacturers to enhance their profit margins while allowing them to reinvest in the business for additional growth opportunities.

𝗚𝗲𝘁 𝗦𝘁𝗮𝗿𝘁𝗲𝗱 𝗧𝗼𝗱𝗮𝘆

Tesla Mechanical Designs provides 𝘀𝗵𝗲𝗲𝘁 𝗺𝗲𝘁𝗮𝗹 𝗺𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗲𝗿𝘀 𝗶𝗻 𝗖𝗮𝗻𝗮𝗱𝗮 with cost-saving drafting solutions that enhance their financial performance. Tesla Mechanical Designs maintains its status as a reliable CAD Design Company by combining outsourcing strategies with advanced CAD technology to help manufacturers develop cost-effective and high-quality designs.

𝗔𝗯𝗼𝘂𝘁 𝗧𝗲𝘀𝗹𝗮 𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝗰𝗮𝗹 𝗗𝗲𝘀𝗶𝗴𝗻𝘀

Tesla Mechanical Designs leads 𝗲𝗻𝗴𝗶𝗻𝗲𝗲𝗿𝗶𝗻𝗴 𝗱𝗲𝘀𝗶𝗴𝗻 𝘀𝗲𝗿𝘃𝗶𝗰𝗲𝘀, concentrating on CAD services, reverse engineering techniques, and prototype development. The Canadian-based Tesla Mechanical Designs combines outsourcing with modern CAD technology to help manufacturers across various sectors reduce costs while enhancing product quality and accelerating production timelines. Tesla Mechanical Designs develops customized solutions to meet each client's unique requirements while securing optimal results for their projects.

No comments:

Post a Comment